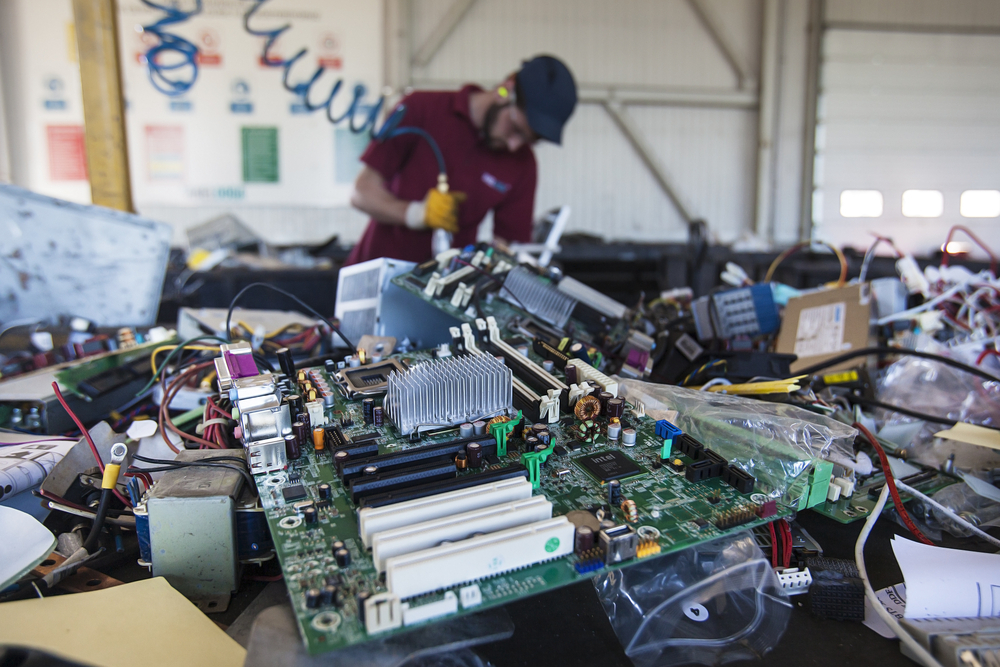

Testing & Shreding

At UAB Insimeta, our main focus is providing electronic waste shredding, seperation and testing services. Our specialized equipment is used to crush the e-waste and select a representative sample, which is then taken to our laboratory for testing. During the testing process we determine the amount of precious metals present and the value of the shipment. We also use the same equipment to separate the less valuable elements. After the testing is complete, the components are sold to recycling factories in Europe and Asia to be used as secondary raw materials for the production of new products.

Description of the e-waste sample process:

The entire shipment (eg. 10,000 kg) is ground to 4cm x 4cm fraction. This is needed to homogenization of the substance.

Most (9,500 kg or more) are more untreated.

The material selected by quarterly 500 kg (5% of the initial mass) is further crushed to 6mm x 6mm fraction.

A 5-10 kg sample is separated from the fourth quarter of the 500 kg material.

Primary grinding (up to 4x4cm) is necessary because the distribution of precious metals on the panels is very uneven and their sizes are various.

This process was combined with several of the largest electronics recyclers in the world (Aurubis, Boliden, and with companies in Sweden and Germany). Many attempts have shown that these fraction sizes and fourth quantities produce the highest accuracy of the sample.